Central Factory Laboratory

The Central Factory Laboratory of LLC "Tashkent Metallurgical Plant" is a key department for production. The CFL is responsible for the incoming control of hot-rolled coils, various solutions, and paint materials, as well as ensuring the quality of the produced galvanized steel and galvanized steel with polymer coating.

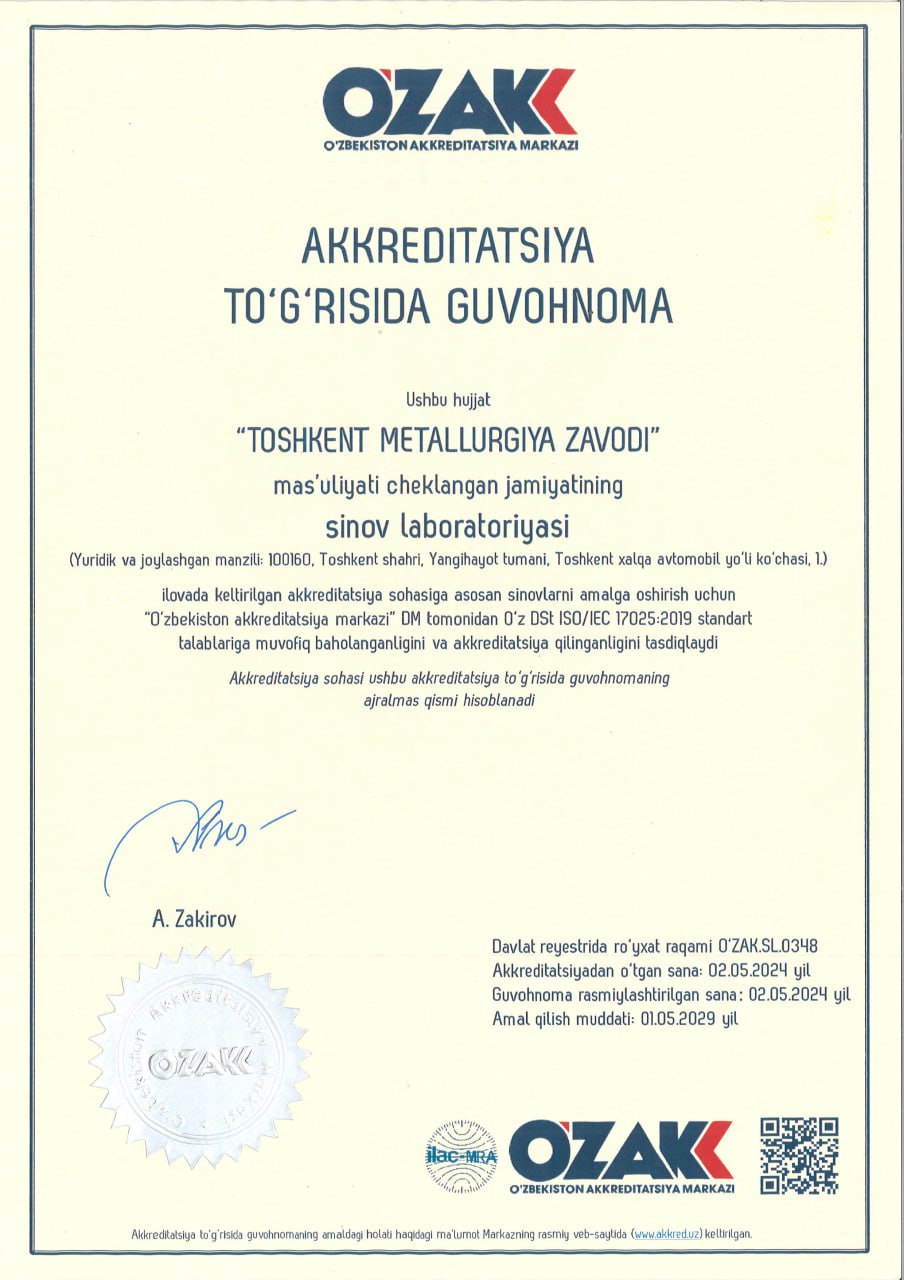

Accredited in accordance with the requirements of the international standard ISO 17025

- The laboratory is equipped with the most advanced equipment produced by global leaders:

himadzu, Walter + Bai AG, TQC, Elcometer, NOVOTEST, FUTURETECH CORP, Beijing TIME High. Technology Ltd, CYMC, BYK, Bruker AXS Q8 MAGELLAN, TESTO, X-RITE, PANTONE, Nikon, and others.

It has highly qualified personnel who have undergone training courses on testing and the competence of testing laboratories (ISO/IEC 17025).

- Modern testing methods are applied.

- The new laboratory premises meet all the requirements for environmental, sanitary-hygienic, fire safety, and safety standards.

The main tasks of the laboratory:

-

Quality control of raw materials and materials

The laboratory conducts thorough analyses of incoming metals and components, ensuring their compliance with regulatory requirements and technological standards.

-

Technical control during the production process

Regular testing at various stages of production allows for the timely detection of deviations and the prevention of product defects.

-

Research and development

The laboratory actively participates in research activities aimed at improving existing technologies and developing new methods of metal processing.

-

Environmental control

Constant monitoring of the impact of production on the environment, as well as conducting necessary analyses to comply with environmental standards.

List of tests

| № | Test Name | Test Object | Test Standard |

|---|---|---|---|

| 1 | Coating mass/thickness | Metal-coated rolled product | DIN EN 13523-12:2017 |

| 2 | Coating mass/thickness | Metal-coated rolled product | DIN EN 13523-7:2014 |

| 3 | Bend test (coating adhesion to steel substrate) | Metallic materials, rolled | O’zDSt ISO 2815:2017 |

| 4 | Tensile test: yield strength, tensile strength, elongation, and reduction of area | Metallic materials, rolled | DIN EN 13523-22:2014 |

| 5 | Tensile test: yield strength, tensile strength, elongation, and reduction of area | Metallic materials, rolled | GOST 29319-92 |

| 6 | Tensile test: yield strength, tensile strength, elongation, and reduction of area | Metallic materials, rolled | DIN EN 13523-15:2014 |

| 7 | Plastic anisotropy coefficient and strain hardening index | Metallic materials, rolled | DIN EN 13523-8:2014 |

| 8 | Spherical indentation depth | Metallic materials, rolled | DIN EN 13523-10:2014 |

| 9 | Plastic deformation coefficient | Metallic materials, rolled | DIN EN 13523-25:2014 |

| 10 | Strain hardening index (strain hardening exponent) | Metallic materials, rolled | DIN EN 13523-26:2014 |

| 11 | Adhesion | Polymer-coated rolled product | GOST 9.401-2018 |

| 12 | Adhesion | Coil-coated metals | GOST 9.407-2015 |

| 13 | Adhesion | Paint and varnish materials (PCM) | GOST 6992-68 |

| 14 | Adhesion | Paint and varnish materials (PCM) | GOST 8420-2022 |

| 15 | Reverse impact resistance (impact test) | Polymer-coated rolled product | GOST 31992.1-2012 |

| 16 | Reverse impact resistance (impact test) | Coil-coated metals | O‘z DSt ISO 3251:2019 |

| 17 | Reverse impact resistance (impact test) | Paint and varnish materials (PCM) | GOST 31973-2013 |

| 18 | Erichsen cupping test (tensile strength of coating) | Polymer-coated rolled product | GOST 9012-59 |

| 19 | Erichsen cupping test (tensile strength of coating) | Metal products with polymer coating | GOST 9013-59 |

| 20 | T-bend test (coating strength) | Polymer-coated rolled product | GOST 13813-68 |

| 21 | T-bend test (coating strength) | Metal-coated rolled product | GOST 18895-97 |

| 22 | Pencil hardness of coating | Polymer-coated rolled product | GOST 2789-73 |

| 23 | Pencil hardness of coating | Metal-coated rolled product | GOST 5639-82 |

| 24 | Color difference | Polymer-coated rolled product | GOST 5640-2020 |

| 25 | Color difference | Metal-coated rolled product | GOST 17261-2008 |

| 26 | Gloss | Polymer-coated rolled product | GOST 9.308-85 |

| 27 | Gloss | Metal-coated rolled product | DIN EN 13523-12:2017 |

| 28 | Gloss | Paint and varnish materials (PCM) | DIN EN 13523-7:2014 |

| 29 | Solvent resistance (abrasion test) | Polymer-coated rolled product | O’zDSt ISO 2815:2017 |

| 30 | Solvent resistance (abrasion test) | Metal-coated rolled product | DIN EN 13523-22:2014 |

| 31 | Dry coating thickness | Polymer-coated rolled product | GOST 29319-92 |

| 32 | Dry coating thickness | Metal-coated rolled product | DIN EN 13523-15:2014 |

| 33 | Dry coating thickness | Paint and varnish materials (PCM) | DIN EN 13523-8:2014 |

| 34 | Scratch resistance | Metal-coated rolled product | DIN EN 13523-10:2014 |

| 35 | Coating adhesion during T-bend | Metal-coated rolled product | DIN EN 13523-25:2014 |

| 36 | Buchholz hardness | Metal-coated rolled product | DIN EN 13523-26:2014 |

| 37 | Visual color difference comparison | Polymer-coated rolled product | GOST 9.401-2018 |

| 38 | Visual color difference comparison | Paint and varnish materials (PCM) | GOST 9.407-2015 |

| 39 | Metamerism | Metal-coated rolled product | GOST 6992-68 |

| 40 | Resistance to salt spray | Metal-coated rolled product | GOST 8420-2022 |

| 41 | Resistance to UV radiation and water condensation | Metal-coated rolled product | GOST 31992.1-2012 |

| 42 | Resistance to humidity | Metal-coated rolled product | O‘z DSt ISO 3251:2019 |

| 43 | Resistance to water condensation | Metal-coated rolled product | GOST 31973-2013 |

| 44 | Salt spray resistance (corrosion spread from scribe) | Polymer-coated rolled product | GOST 9012-59 |

| 45 | Appearance assessment | Polymer-coated rolled product | GOST 9013-59 |

| 46 | Atmospheric resistance | Polymer-coated rolled product | GOST 13813-68 |

| 47 | Conditional viscosity | Paint and varnish materials (PCM) | GOST 18895-97 |

| 48 | Density (pycnometric method) | Paint and varnish materials (PCM) | GOST 2789-73 |

| 49 | Mass fraction of non-volatile, volatile, solid and film-forming substances | Paint and varnish materials (PCM) | GOST 5639-82 |

| 50 | Degree of dispersion | Paint and varnish materials (PCM) | GOST 5640-2020 |